Empowering Business Excellence

Maintenance Management

At GOS, we specialize in crafting strategic solutions that drive growth and enhance operational efficiency for businesses worldwide.

Maintenance Management

MAINTENANCE MANAGEMENT SYSTEM

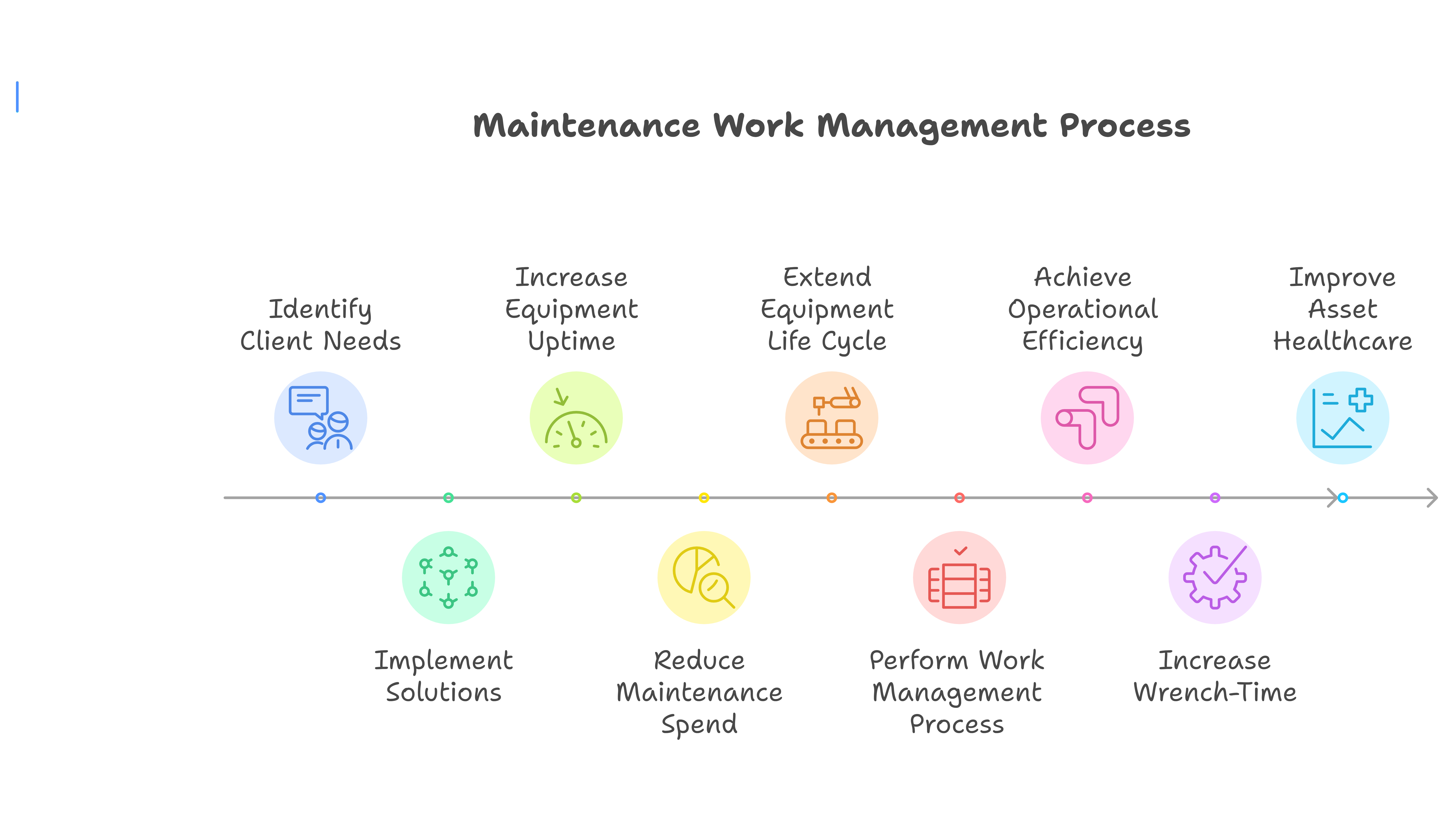

GOS consulting implements maintenance work management solutions for its clients in partnership manner to increase equipment uptime, reduce maintenance spend and extend equipment life cycle. Performing the work management process in its optimal capability is a key success to meeting the operational efficiency, reduce unplanned downtime, mitigate toward proactive maintenance. Our skilled team has a deep expertise in developing, implementing and improving the entire work management process ensuring sustainable results. The outcome of this work management process is to increase wrench-time, attainment of the preventive and predictive maintenance, and improve overall asset healthcare.

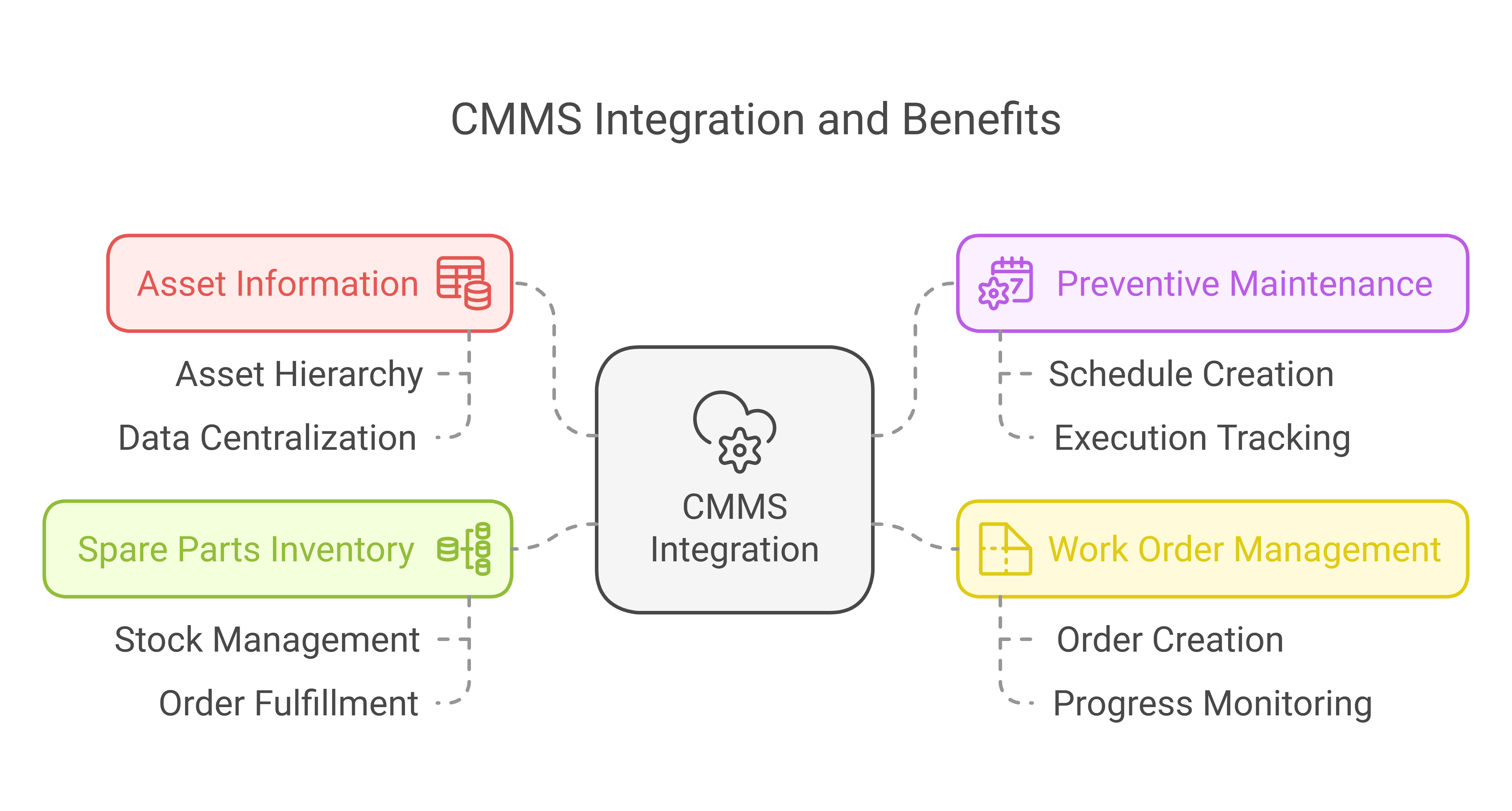

CMMS INTEGRATION – MASTER DATA

Computerized Maintenance Management Systems (CMMS) platforms play a crucial role in effective maintenance practices, particularly around PM and work order management and execution. This begins with good master data management of the asset hierarchy list and connects into the Maintenance Management Operating System (MMOS) and how we use information from the CMMS. An effective CMMS supports the maintenance organization by centralizing asset information, driving preventive maintenance schedules and work orders, tracking work order execution, and managing spare parts inventory. GOS consulting optimizes CMMS so that our clients can benefit from improved asset reliability, enhanced maintenance efficiency, reduced downtime, better resource allocation, and increased overall productivity.

MAINTENANCE MANAGEMENT

GOS consulting works with clients to close the gap that often exists between annual planning and business objectives and daily operational execution. Our team works closely collaborating with client leadership teams to ensure organizational goals are in sync with operational strategies and systems for managing. Our team supports annual strategic sessions by holding workshops to determine corporate objectives in line with the company vision, and the resulting operating strategy to support this corporate plan. Further, we help to define the resulting performance and capability requirements to support the operating strategy, and what initiatives are necessary to deliver on the annual plan. This encompasses overarching business strategy along with nearly all functional areas to ensure the necessary capabilities and performance are in place to drive the intended results and value.

GOS consulting specializes in implementing MRO (Maintenance, Repair, and Operations) material management solutions for our clients. Without effective MRO materials management, various challenges can arise, such as inventory stockouts, increased maintenance costs, prolonged equipment downtime, and inefficient maintenance processes. By implementing robust MRO materials management strategies, companies can optimize stocking strategies and inventory levels, reduce lead times for critical spare parts, enhance equipment reliability, and ensure technicians have what they need to execute work orders. Our tailored solutions ensure that the right materials are available at the right time, enabling our clients to improve wrench time and resource utilization. Elevate your maintenance organization with our expertise and realize the benefits of efficient MRO materials management.

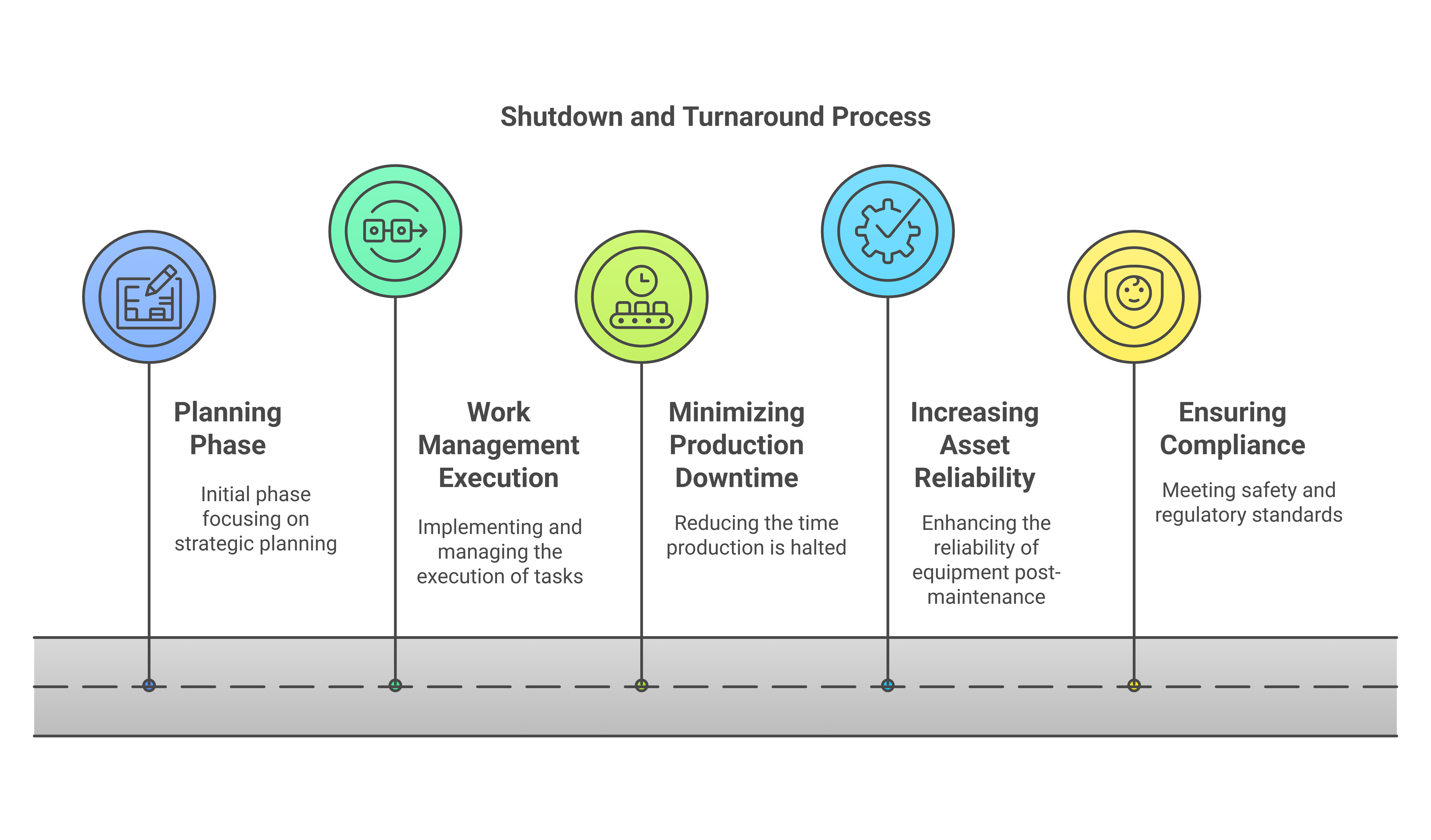

SHUTDOWN – OUTAGE MANAGEMENT

Shutdowns and Turnarounds are important aspects of running an operation, particularly in asset intensive and continuous process industries. Improvements are critical processes focus on enhancing the efficiency and effectiveness of planned maintenance activities and to safely bring the equipment back up within the intended timeframe. Optimization of shutdown and turnaround processes begins with effective planning and ultimately effective work management execution. These processes running swiftly and effectively help to minimize production downtime, increase asset reliability once the equipment is back online, and ensure compliance with safety and regulatory standards.